Basic Info

| Model NO. | DEBAO-118C |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | Have |

| Transport Package | Standard Export Packing |

| Specification | 3-16 |

| Origin | Wenzhou |

| HS Code | 8441309000 |

| Production Capacity | 1000-3000set/Year |

Product Description

| Model | Speed | Price

(FOB Ningbo) | Optional Inspection | Optional

Paper feeder | Delivery Time | Guarantee | Payment |

DEBAO-138S

2-16OZ

| 110-160pcs/min | / | / |

/ | 60 working days

| 5 years for mechanical,

1 year for electrical | TT

30% deposit, 70% before delivery. |

| Machine parameter |

| Paper type | Paper grams | Cup size range | Total Power | Air request | Weight | Packing size |

| One/two PE | 210-330g/m2±20g | (D1)Φ60-95mm (H)50-135mm

(D2)Φ40-75mm (h)5-12mm | Three-Phase 380V, 31KW | 0.5-0.8Mpa, 0.5Cube/min | 3500KGS | 3.1*1.6*2.35m, 1.23*0.61*1.9m |

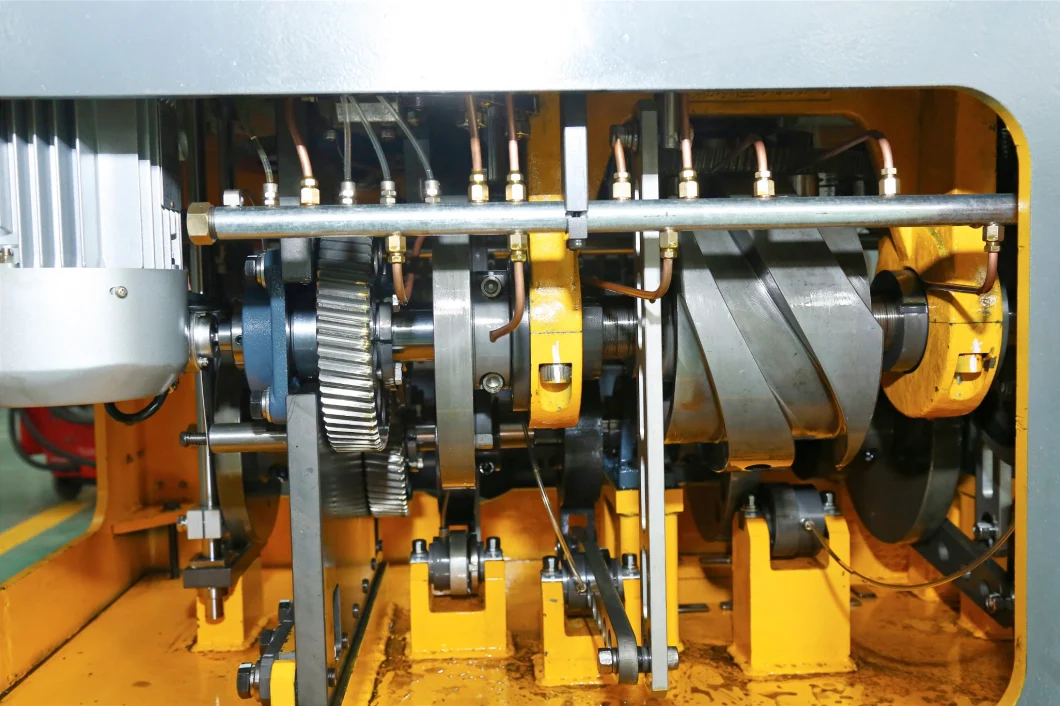

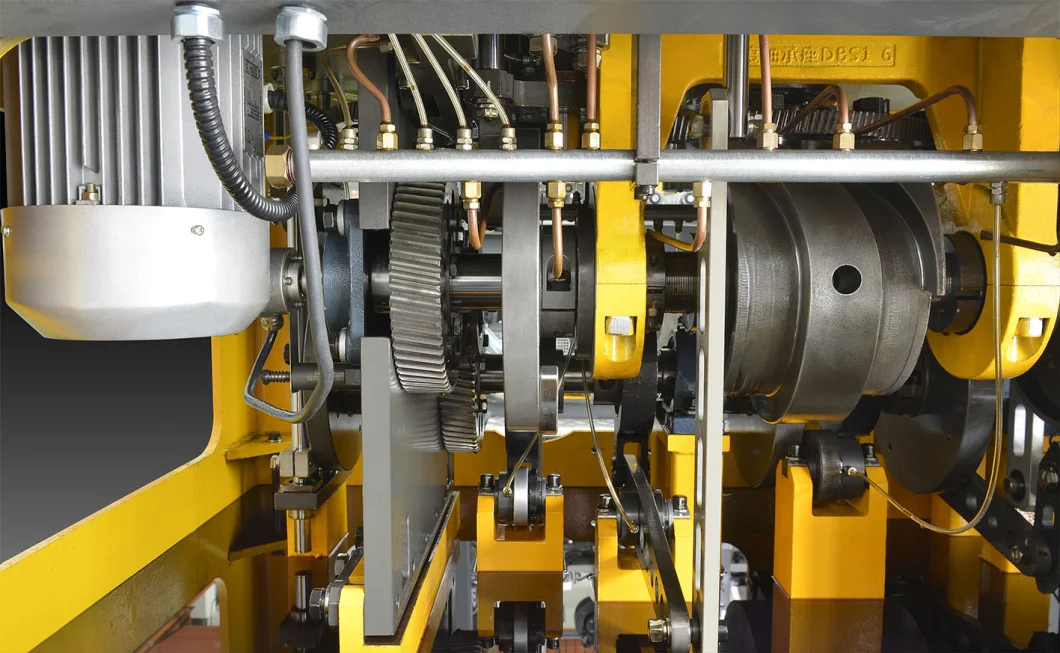

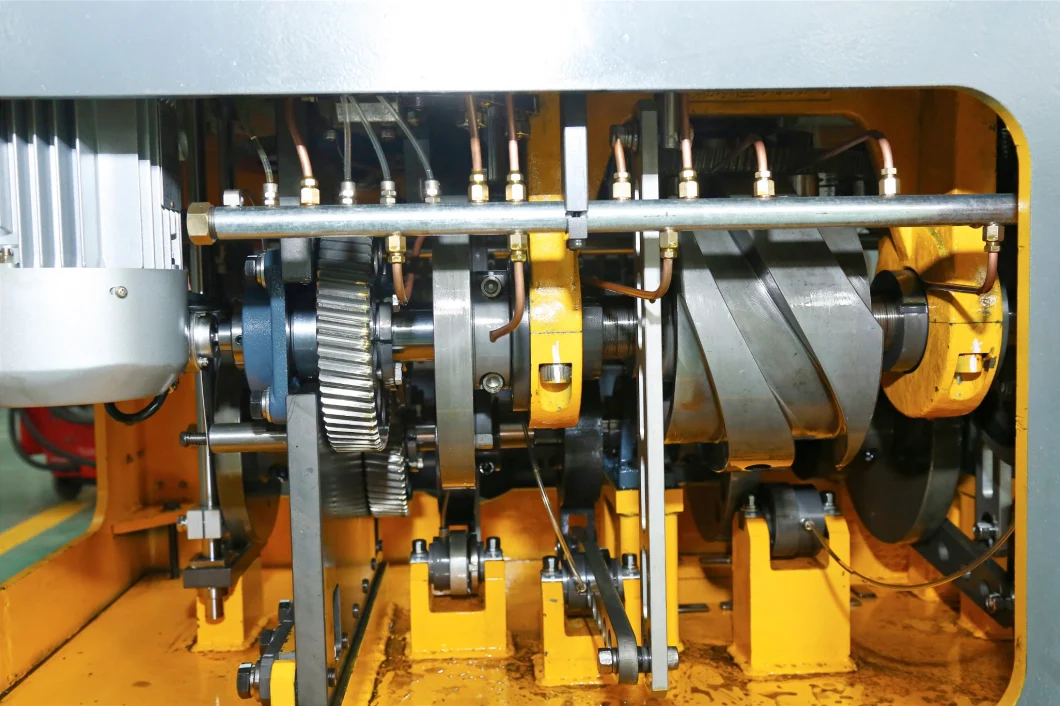

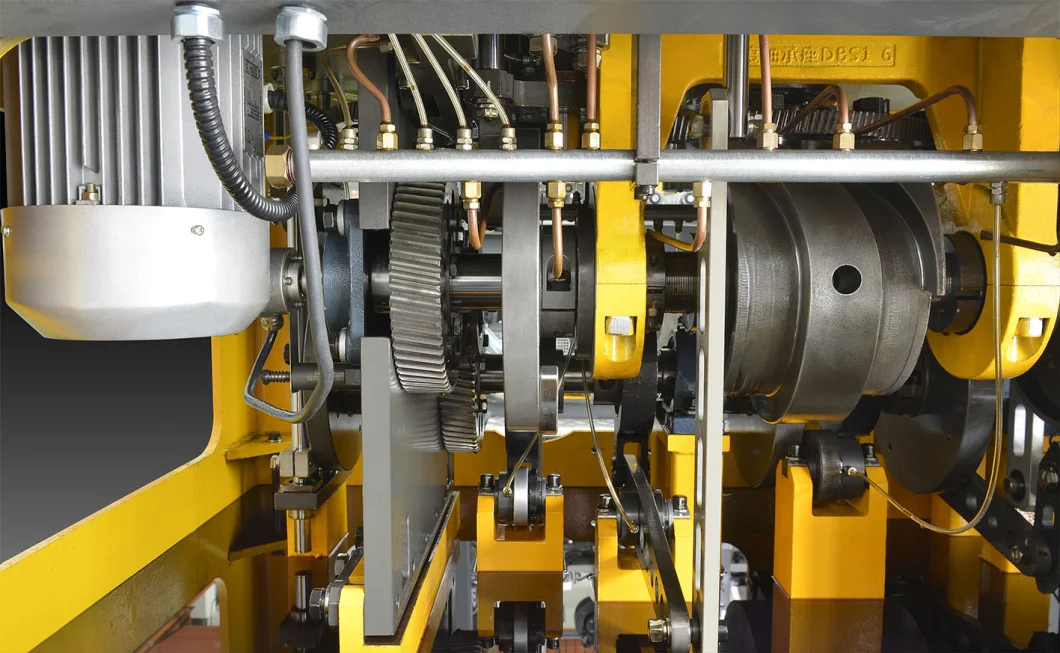

Stability1.1-Longitudinal axis gear drive. Cylindrical barrel indexing cam. This design optimize machine internal layout,ensure machine drive precision.So makes the each part coordination and prevent machine part collision. This make up the chain drive jitter and instability's weakness.

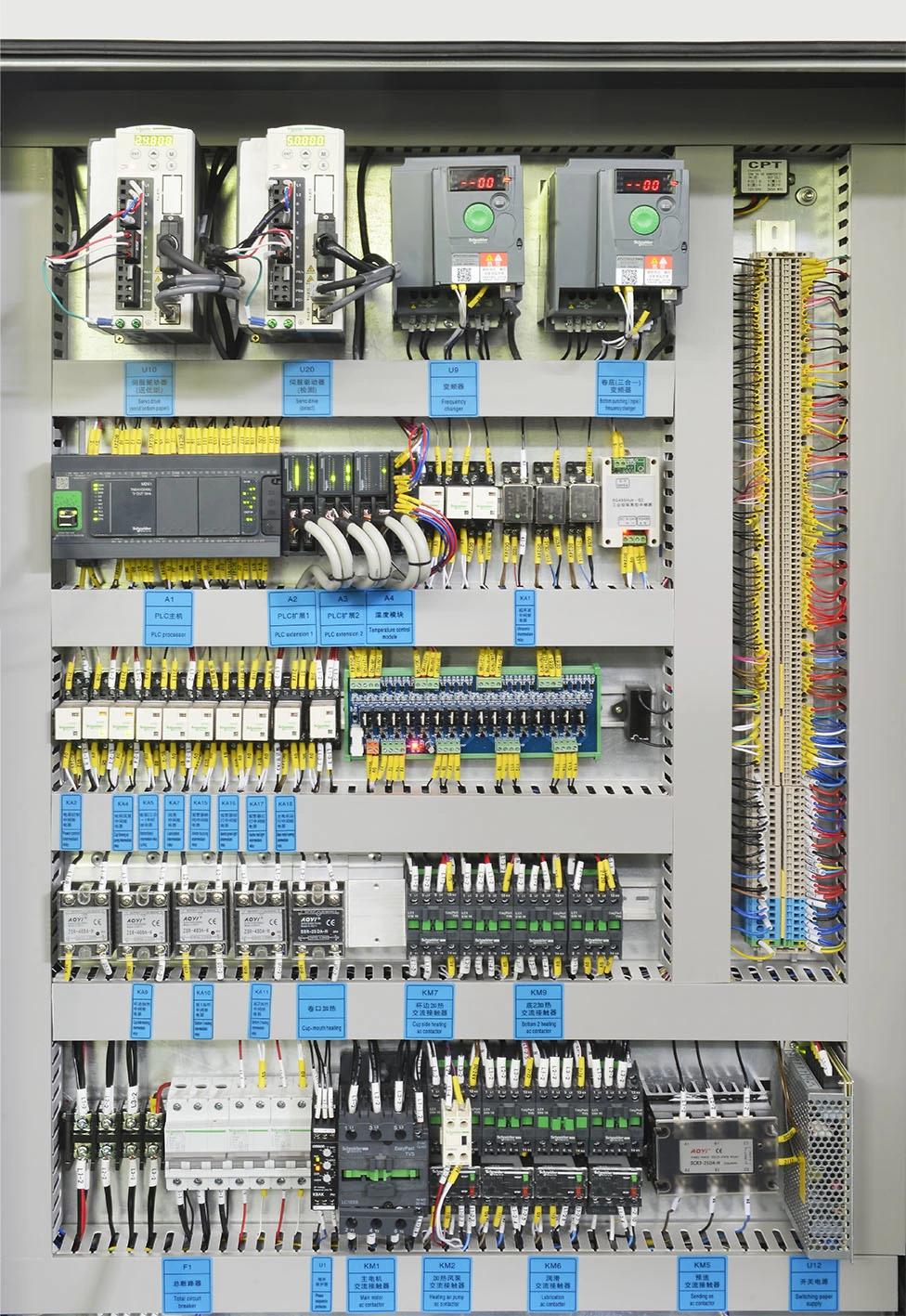

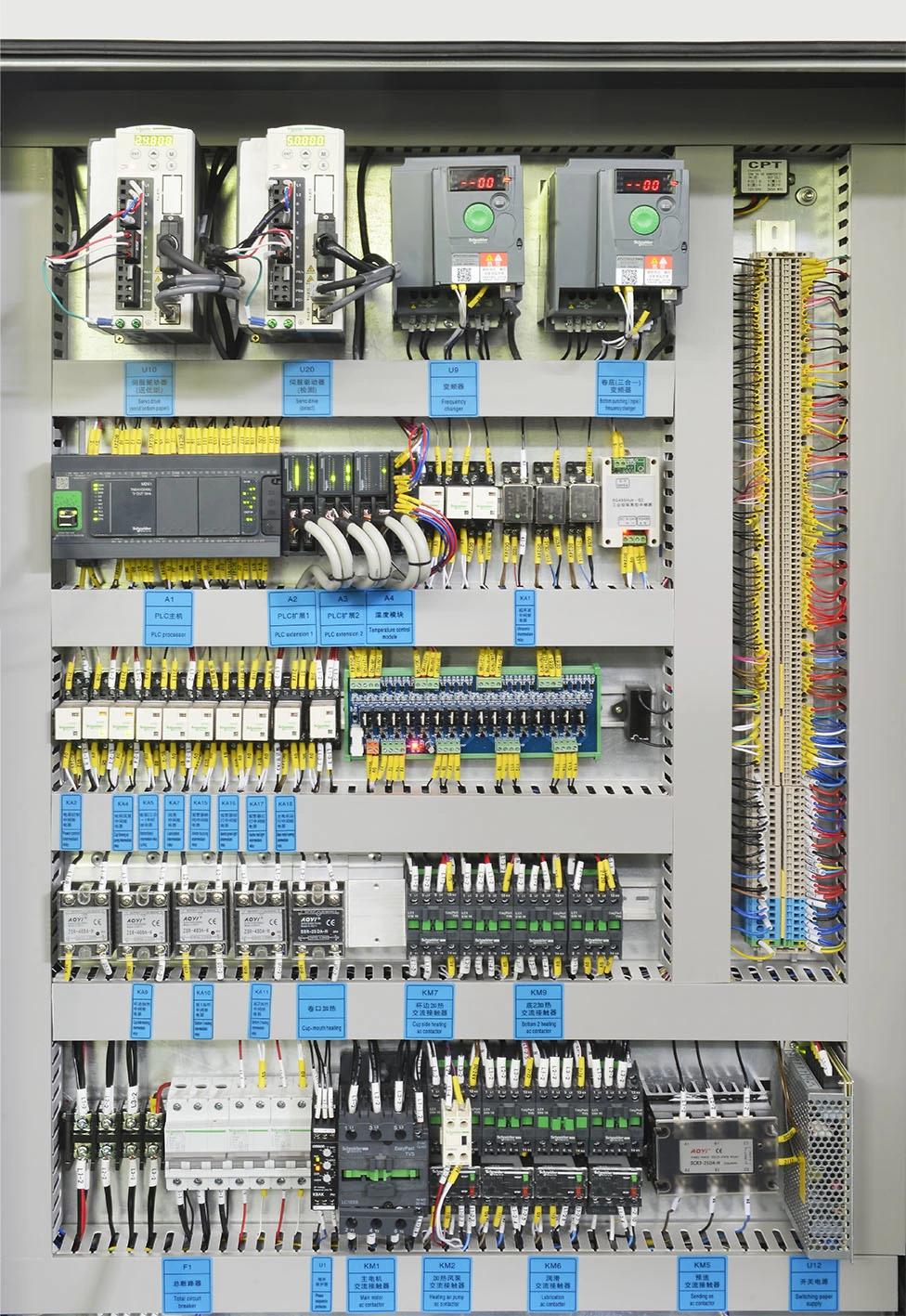

1.2-Box structure design and oil spray lubrication system, reduce damage and cooling effective. Then machine can run fast. Due to box structure and insulate bottom&top, oil only change 2 times each year(circulate 6 months). It makes machine easy maintenance and save oil costs. If other factory reach same lubrication affect, they have to change oil each month. Because paper dust and waste fall down to bottom due to their unclosed structure.Intelligent 2. 1 electrical parts. Machine whole control system PLC & touch screen with sensors. Servo feeding paper to reduce waste. Any breakdown occur, it auto-stop and show on screen for easy checking. With electronic cam, machine can adjust paper suction rod position etc on screen. PID temperature control system for heater, can set temperature on screen also. Other factories rotate button to control temperature manually, so it will have deviation.

2.2-Optional with Detector. Two step CCD Camera system checking for cup quality, include top curling,bottom kurling. Also any dirty in the cup, the detector will seek out and send to final bad cup waste box by separate pipe.

3. Two process for curling-First curling use the internal expanding rotational molding to improve paper forming intensity. Second curling process use heat setting which make very nice curling mouth and keep dimension stability.

-