12oz Beverage Single Layer Paper Cup Lid Making Machine Production Lines

Basic Info

| Model NO. | YGD-120SP |

| Warranty | 12 Months |

| Applicable Objects | Beverage |

| Cup Size(Ounce) | 2-12OZ |

| Speed | 80-100pcs/min |

| Required Paper | Double Side PE Coated Paper |

| Automation | Automatic |

| Logo Printing | Without Logo Printing |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | 12 Months |

| Total Power | 220V/380V,50/60Hz,6 Kw |

| Dimensions | 2250*1300*1900mm |

| Cup Collection | 900*1600*900mm Optional |

| Weight | 2200kgs |

| Working Air Source | 0.4-0.5m3/Min |

| Transport Package | Wood Case |

| Specification | Customizable |

| Trademark | YG |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 172800 Per Day |

Product Description

Paper Cup Marking Machine

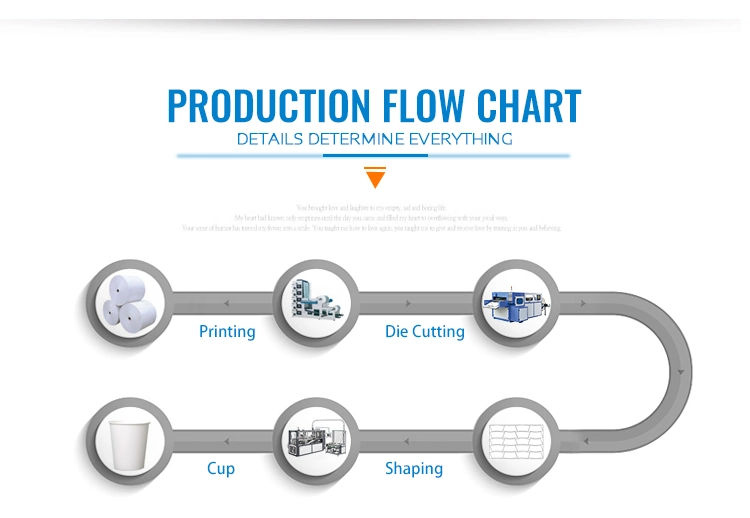

1, Paper cup machine for producing paper cup, tea cup, coffee cup, advertisement cup, ice cream paper cup or other food.

2, Automatic control adopts optically controlled non-contact switch, Micro-controlled transducer,Step-less speed adjustment

3, Easy changing molds produce different sizes paper cups

4, Easy operating by operator (one operator is enough)

5, Easy maintenance with minimum cost

Our newly designed paper cup forming machine is a fully automatic paper cup forming machine, which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding through more than 2 times, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by magic hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre-heating, bottom knurling, cup discharging. The machine, researched and developed by our company, is improved in stability after comprehensive technical improvements.

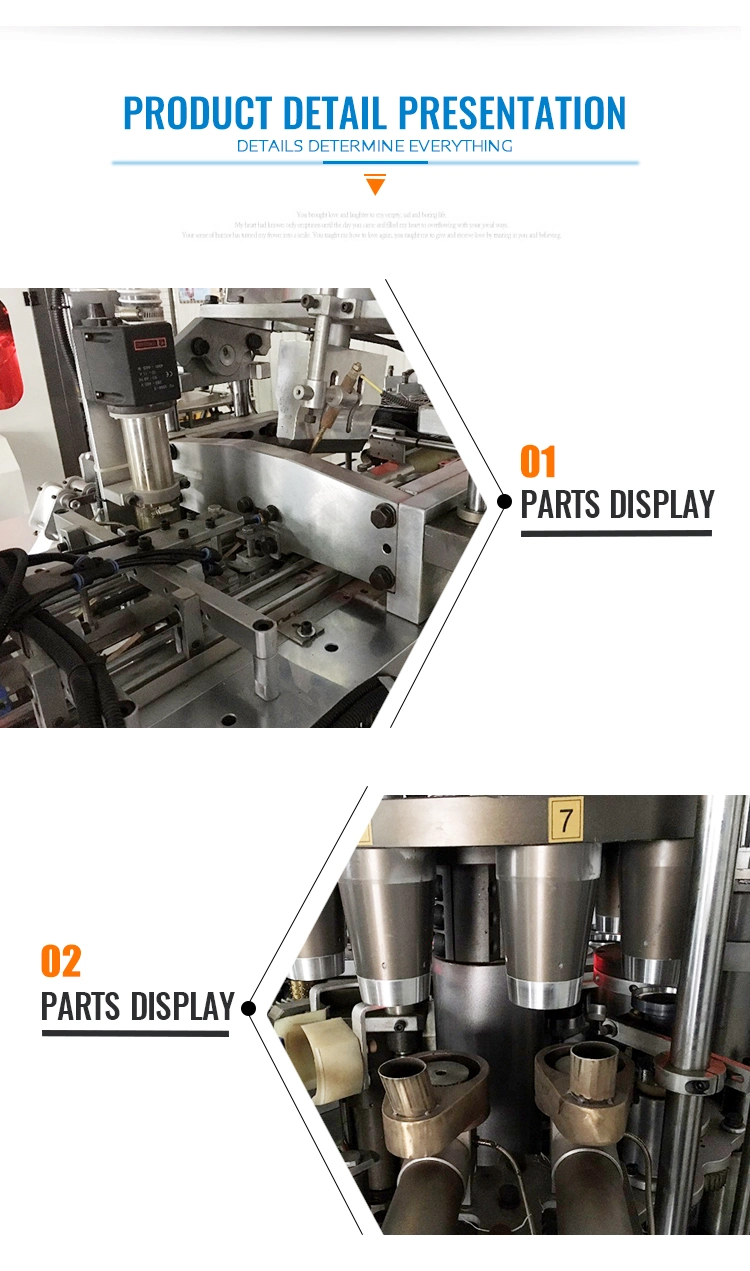

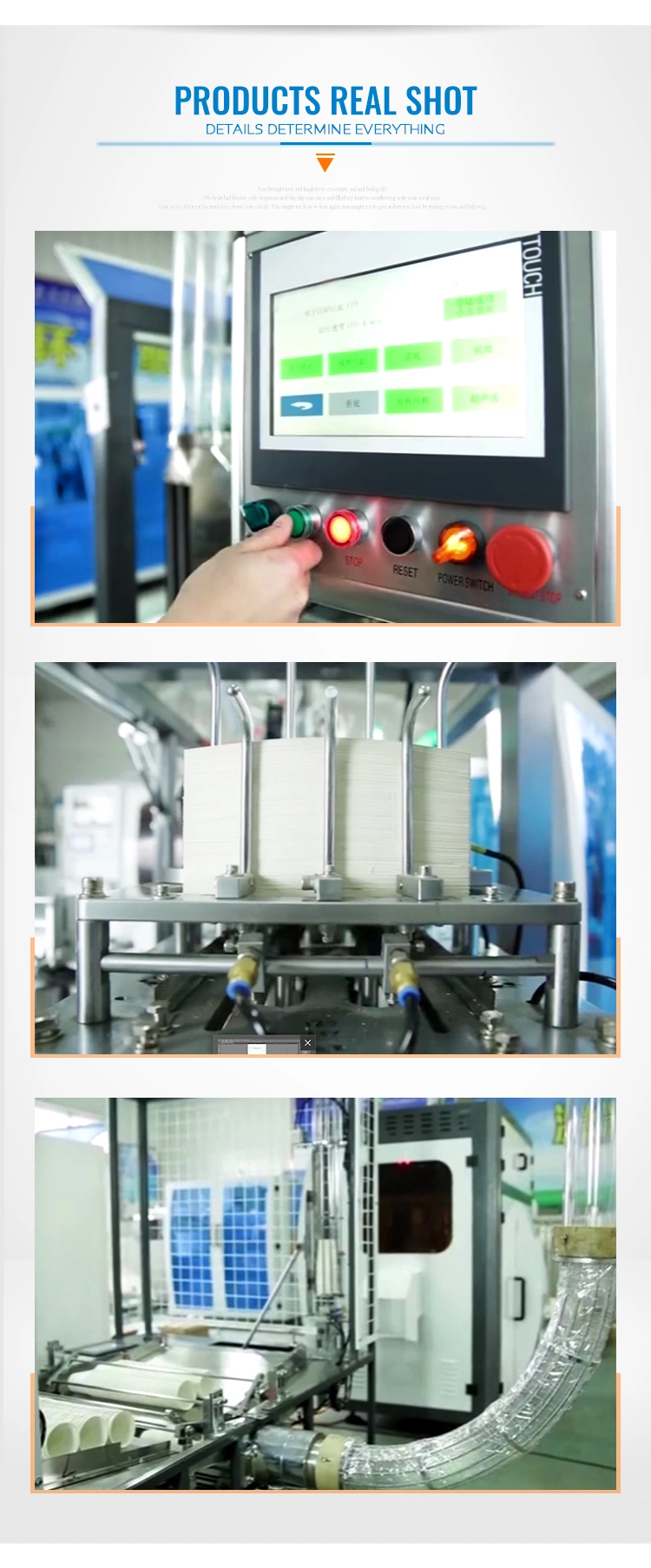

Detailed Photos

Model | YG-800 | YG-C800 | YG-S800 | |

Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

Raw Material | One-side PE | One-side PE | One-side or two-side PE coated paper | |

Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

Suitable paper weight | 150-180g/m²;±20g/m² | 150-300g/m²;±20g/m² | 160-300g/m²;±20g/m² | |

Voltage supply | 380V,50HZ | 380V,50HZ | 380V(220V) 50HZ | |

cup size | Bottom35-70mm, | Bottom35-70mm,Top45-90mm, | Bottom35-70mm, | |

General power | 4.5 kw | 5 kw | 6kw | |

Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m³/min | |

Net weight | 1680kg | 1680kg | 2000kg | |

rement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

Cup holder | L:900mm;W:600mm;H:1500mm | |||

Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

Bottom Knurling | Heating | Heating | Hot Air System | |

We can customize machine and mold according to customer's requirement. | ||||

The difference between ultrasonic paper cup machine and copper strip paper cup machine

The difference between ultrasonic paper cup machine and copper strip paper cup machine

The ultrasonic heater type is equipped with a hot air blowing system, which can provide hot air to ensure the perfect adhesion of the bottom of the cup, and the finished cup does not have any water leakage problems (much better than the ordinary bottom heater). Only the ultrasonic heater type machine is equipped with a hot air system, and the copper heater type machine is not equipped.

Paper Cup Making Machine Feature

1. Excellent steel frame;

2.Professional humanized design;

3.Simple operation panel;

4.Simple operation and convenient maintenance;

5.Stable transmission system;

6.High-quality products with low consumption;

7.Safe alarm system;

8.Double-layer insulation bowl machine.

CertificationsPackaging & ShippingCompany Profile