Second Hand Small Automatic Pulp Forming Egg Tray Machine

Basic Info

| Model NO. | jc |

| After-sales Service | 7X24 |

| Warranty | 720 |

| Certification | CE, ISO, GOST |

| Condition | Used |

| Customized | Non-Customized |

| Automatic Grade | Automatic |

| Structure | Horizontal |

| 1 | 2 |

| 2 | 3 |

| 3 | 4 |

| 5 | 4 |

| Transport Package | Wooden Case |

| Specification | STANDARD CONTAINER |

| Trademark | FINEYEAR |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 1000 Sets Per Year |

Product Description

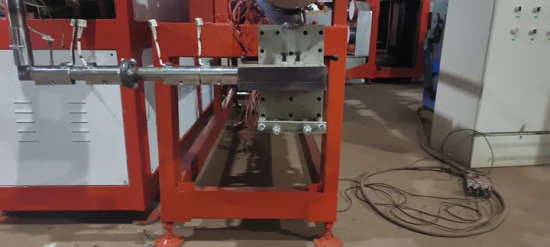

we supplied all kinds of used/second hand/old rubber processing machines including tire machines,conveyor belt machins,rubber track machines,etc.Specification

1. Application:

the pin barrel rubber extruder is mainly used for the shaping extrusions of rubber compounds at room temperature. when fitted with different extruder heads, it can achieve many rubber products in rubber industry, for example, exruding of inner tubes and tire treads, coating of rubber tube and conveyor belt, shaping extrusion of profiles of rubber sheet and plate. in addtion, it also incorporates into a multiple extrusion unit together with other (hot or cold feed) rubber extruders.

pin barrel extruder has good plastifying and mixing properties which can result in uniformity goods, low extrusion temperature , high extrusion capacity , low powe consumation, wide processing adaptability.

2 Structures features:

the pin barrel extruder consists of motor , reduction gear box, feed device, screw, barrel, extrusion head, temperature control unit, electric control device and frame , and so on.

- main motor is a DC motor with DC speed adjuster, gear reducer is multi-step tooth surface hardened type, and immersion lubrication/oil pump are adopted.

- feed device is double-walled design for water cooling, and feed roll is designed for water cooling with a rotary joint and adjustable scraper knife for continuous cleaning and is driven by splined coupling ring.

- screw is made of nitrided steel 38CrMoAIA, surface hardened by nitriding, nitriding depth 0.5~0.7mm, and surface hardness 900HV, extrusion barrel is drilled for water cooling and heating with 7~12 pin rows,each have 6~12pins and is made of nitrided steel 38CrMoAIA in bore surface hardened by nitriding, nitriding depth 0.5~0.7mm, and surface hardness approx.950HV.

- temperature control unit(TCU) for the cooling of screw, pin barrel, feed barrel, feed roll, and extrusion head.

- frame is welded by steel profiles.

3. technical specifications:

| model | screw | barrel | motor (kw) | temp.control unit | Max.capacity | |||||

diameter (mm0 | L/D | Max.speed(r/m) | length (mm) | number of pin row/pins in each. | zones | power | (kg/h) | |||

| XJD-60x12D | 60 | 12 | 80 | 720 | 7/6 | Z4 | 18.5 | 3 | 2.2*3 | 120 |

| XJD-65X12D | 65 | 12 | 80 | 780 | 7/6 | Z4 | 22 | 3 | 2.2*3 | 160 |

| XJD-90X12D | 90 | 12 | 60 | 1080 | 7/6 | Z4 | 45 | 4 | 6*4 | 320 |

| XJD-90X14D | 90 | 14 | 60 | 1260 | 7/6 | Z4 | 55 | 4 | 6*4 | 350 |

| XJD-120X12D | 120 | 12 | 50 | 1440 | 8/6 | Z4 | 75 | 4 | 6*4 | 650 |

| XJD-120X14D | 120 | 14 | 50 | 1680 | 10/6 | Z4 | 90 | 4 | 6*4 | 700 |

| XJD-120X16D | 120 | 16 | 50 | 1920 | 10/8 | Z4 | 110 | 4 | 6*4 | 750 |

| XJD-150X12D | 150 | 12 | 45 | 1800 | 8/8 | Z4 | 160 | 4 | 10*4 | 1500 |

| XJD-150X16D | 150 | 16 | 45 | 2400 | 10/8 | Z4 | 185 | 4 | 10*4 | 1700 |

| XJD-200X12D | 200 | 12 | 30 | 2400 | 8/10 | Z4 | 220 | 5 | 12*4 | 2200 |

| XJD-200X16D | 200 | 16 | 30 | 3600 | 12/10 | Z4 | 355 | 5 | 12*5 | 2500 |

| XJD-250X12D | 250 | 12 | 25 | 3000 | 8/12 | Z4 | 450 | 4 | 16*4 | 3800 |

| XJD-250X18D | 250 | 18 | 26 | 4500 | 12/12 | Z4 | 550 | 5 | 16*5 | 3800 |

Application:

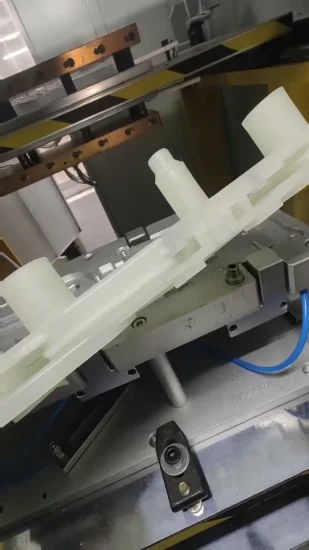

The machine is suitable for ATV sand tire building,applicable for tire shell forming 6-18''. Adopting radial expanding and shrinking,manual turn up.

Main technical spec.:

Applicable size | 6", 8"-18" |

Forming type | Flat drum expanding type |

Building drum rotation speed(r/min) | 25-140 |

Working air pressure(MPa) | 0.8 |

Ply roll dia.(mm) | Φ500 |

Ply width(mm) | 900 |

Liner cloth roll dia.(mm) | Φ250 |

Motor power(kw) | 2.2 |

Fabric supply layer | 3 |

Fabric supply device | 0.55kw |

Host overall dimension(L*W*H)(mm) | 4150*1250*2000 |

Fabric supply dimension(L*W*H)(mm) | 2800*1900*1400 |

Weight(kg) | Host 1630, Fabric supply800 |

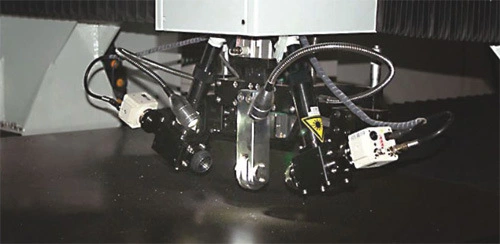

| Model | JC-RH50-250CC | JC-RH65-250CC | JC-RH200-1000CC(A) | JC-RH200-1000CC(B) | JC-RH260-1500CC | JC-RH300(A) | JC-RH300(B) | |

| Shot Voolume | C.C | 300 | 300 | (1000)~1500 | (1000)~1500 | (1500)~2000 | (2000)~3000 | (2000)~3000 |

| Injection pressure | Kg/cm2 | 1700-1800 | 1700-1800 | 1700-1800 | 1700-1800 | 1700-1800 | 1700-1800 | 1700-1800 |

| Lnjection Hydraulic pressure | Kg/cm2 | 150 | 150 | 150-160 | 150-160 | 150-160 | 150-160 | 150-160 |

| Screw Diameter | mm | 32 | 32 | 45 | 45 | 45 | 50 | 50 |

| Screw Speed | Rpm/min | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 |

| Material Size | mm | 10×30 | 10×30 | 12×50 | 12×50 | 12×50 | 15×60 | 15×60 |

| Clamping Force | TON | 60 | 60 | 200 | 200 | 260 | 300 | 300 |

| Piston Stroke | mm | 360 | 370 | 460 | 460 | 580 | 510 | 510 |

| Plate Size | mm | 350×380 | 290×320 | 480×500 | 550×620 | 520×580 | 650×730 | 550×650 |

| Space Between Tie Bar | mm | 445 | 390 | 575 | 675 | 645 | 790 | 690 |

| Piston Diameter | mm | 180 | 200 | 356 | 356 | 406 | 430 | 430 |

| Motor | kw | 5.5 | 5.5 | 11 | 11 | 15 | 18.5 | 18.5 |

| Heating Capacity | kw | 7.2 | 7.2 | 13.6 | 13.6 | 16 | 19 | 18 |

| Thermal Oil Pump | hp | 1/2×1 | 1/2×1 | 1/2×2 | 1/2×2 | 1/2×2 | 1/2×2 | 1/2×2 |

| System pressure | Kg/cm2 | 210 | 210 | 210 | 210 | 210 | 210 | 210 |

| Machine Dimensions | mm | 2275×1705 ×2900 | 2135×1240 ×2870 | 3610×2000 ×3730 | 2275×2095 ×3715 | 2750×2130 ×3780 | 2900×2355 ×4400 | 3000×2345 ×4470 |

| Machine Weight | kg | 2300 | 2200 | 5800 | 6500 | 6800 | 8500 | 7500 |

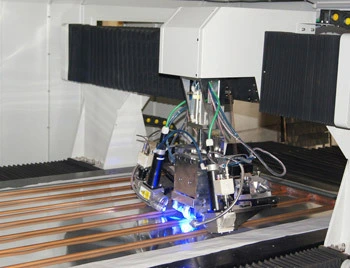

Advertising PVC banner flex sheet production line machine/ cloth printing fabric making machine

Note: We can design the different size of machine according to the requests for products.

1, Other Name:

PVC banner flex making machine

SY-5F 610*1830mm PVC film making machine for banner flex

pvc banner flex making machine

PVC banner flex making machinery, PVC flex banner production line

Plastic film recycling line/PP PE film recycling line/pvc banner flex making machine

3.2M 0.25-2MM PVC banner flex making machine

pvc flex banner making machine

PVC flex banner sheet making machine

Advertising PVC banner flex sheet production line machine

PVC flex banner sheet production line making machine

pvc banner flex making machine/flex background banner,pvc banner flex making machine

2, Description:

This equipment adopts the 3-in -one structure of film--glass fiber mesh cloth--film or 2 in one with films and glass fiber mesh cloth structure, which can be made into flex banner , inkjet Print, AD print etc,which can be used everywhere for public projects, such as the exhibition hall, museum, library, gymnasium, art, display hall, opera, university, middle school; besides, it can also be used for AD sales. For more important, its function can appear for the public lighting system, such as the square, parks, construction display project for the airport and railway stations; Additionally, it can beautify the whole wall, which make people feel warm and beautiful, such as the hotels, canteens, teashops, sack houses, bars, balls, gym etc.

3, Advantages:

1. With equal thickness, having good ink absorption and strong color appearance

2. High density for the connection of PVC and mesh cloth.

3. Heating by mirror rollers

4. No need to paste glue, compound with hot pressing.

5. With automatic winder, easy for operating.

6.Correct temperature control, equal control for tension.

7. All heating rollers has been process precisely, with high precision and good balance for the concentricity and coaxality.

8. With good temperature protection for the heating rollers, with low loss of power.

9. Main electrical parts adopt famous foreign brand, with good stability and credibility ,

10. This equipments have the advantages of big capacity, high efficacy, stable quality, easy operation and etc, it is the best choice for Ad customers.

4, Parameters:

1, Available width 3200MM

2, Diameter for mail roller 1000MM

3, Length of roller face 3600mm

4, Working speed 5~15M/min

5, Heating method Hot oil conduct heating

6, Power for hot stove 1000000 Kal/h

7, Power for electricity About 20KVA

Parameter Product Type | XJ-65 | XJ-85 | XJ-115 | XJ-150 | XJ-200 | XJ-250 |

Screw Thread Type | Dual Head Same | Dual Head Same | Dual Head | Dual Head | Dual Head | Dual Head |

Screw Exterior Dia. | 65 | 85 | 115 | 155 | 200 | 250 |

Ratio L/D | 4 | 4.3 | 4.8 | 4.43 | 4.35 | 4.5 |

Condensation Ratio | 1.3 | 1.3 | 1.34 | |||

Screw Rotate Speed r/min | 20.27.35.47 | 28.40.56.80 | 33.46.60 | 27-81 | 22.4-67.2 | 19.7-59.1 |

Motor Power kw | 7.5 | 11/15 | 22 | 18.3-55Commutator Motor | 25-75Commutator Motor | 33.3-100Commutator Motor |

Throughput kg/n | 50-80 | 70-210 | 100-420 | 700-1200 | 1500-2200 | 2000-3200 |

Steam Pressure Mpa | 0.2-0.3 | 0.3-0.4 | 0.4-0.6 | 0.6 | 0.6-0.8 | 0.6-0.8 |

Cold Moving Water Pressure Mpa | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2 | 0.2-0.3 | 0.2-0.3 |

Condensed Air Pressure Mpa | 0.3-0.6 | 0.6 | ||||

Overall Size: LxWxH(mm) | 1630x604 | 2050x700 | 1630x604 | 3411x814 | 4564x1800 | 4950x1150 |

Product Weight kg(not include the head) | 1200 | 2500 | 3000 | 5000 | 8000 | 11400 |

open mixing mill

| Detail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||