Factory Price Paper Eggs Tray Carton Making Machine Egg Tray Molding Machine for Sale

Basic Info

| Size | Small |

| Condition | New |

| Applications | Egg Tray Making Machine |

| Product Type | Egg Tray Machine |

| Processing Type | Pulp Molding Machine |

| Production Speed | 1000~8000 PCS/Hour |

| Product Name | Egg Tray Machine |

| Raw Material | Waste Old Book, Waste Newspaper, Waste Carton |

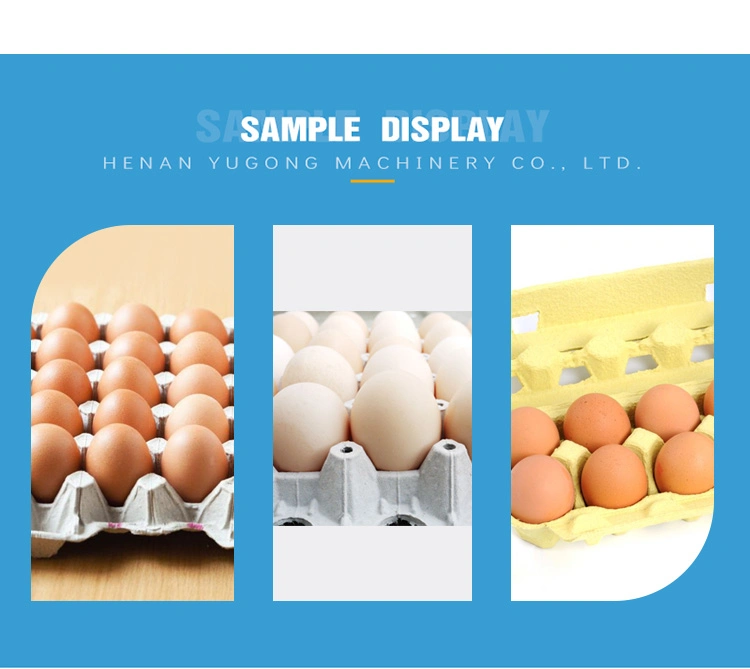

| Finished Products | Egg Tray, Egg Carton, Fruit Tray, Shoe Tray, Wine |

| Drying Way | Natural Drying, Brick Kiln Drying, Metal Dryer |

| Mould Type | 6 Cells,10 Cells,12 Cells,18 Cells,30cells or Cust |

| Mould Material | Plastic or Aluminium |

| Transport Package | Wooden Cases or Container |

| Specification | 2800*1400*1700mm |

| Trademark | YG |

| Origin | China |

| Production Capacity | 1000PCS/Month |

Product Description

Introduction of egg tray making machine:

Our egg tray making machine is suitable for variety scale production plant.It can produce egg cartons, egg box, egg tray, bottle holder, agricultural culture fruit tray, coffee cup tray,ect.The product can be recycled, is a new green packaging, is not only the development of environment-friendly enterprise, also long get rich choice.

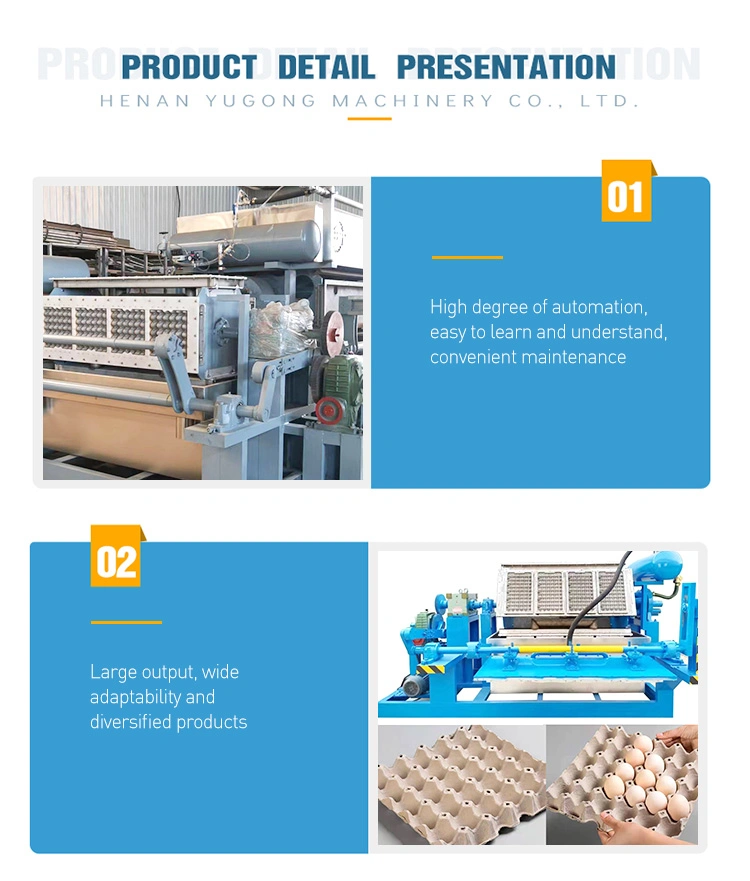

Main Features:

High precision servo motor drive,high efficiency and energy-saving drying line.

1,Use precision reducer servo motor forming and transferring to ensure smiith and fast operation.

2,Use absolute encoder to achieve accurate correction.

3,The use of bronze casting static and dynamic ring structure is more suitable for product dewatering process.

4,The use of mechanical structure to ensure that the mold close on both sides evenly.

5,Large capacity; Water content is low;Save the cost of drying.

Production Process:

1. Pulping system

(1) Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

(2) Put the pulp in the slurry tank into the pulping tank, adjust the pulp concentration in the pulping tank, and further stir through the homogenizer through the white water of the return pool and the thick slurry of the storage tank. After adjusting to the applicable pulp, put it into the feeding pool to be used in the molding system.

Equipment used: pulping machine, homogenizer, slurry pump, vibrating screen, pulp disintegrator

2. Forming system

(1) The pulp in the supply tank is supplied into the molding machine, and is adsorbed by the vacuum system, and the pulp is left on the mold by the mold on the equipment to be formed, and the white water is sucked and transported back into the pool through the vacuum pump.

(2) After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

Equipment used: molding machine, mold, vacuum pump, vacuum tank, pump, air compressor, mold cleaning machine

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.

(2) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood,A heat source such as liquefied petroleum gas.

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy compared to transmission drying. The main heat source is clean energy such as natural gas, diesel oil, liquefied petroleum gas and methanol.

4. Finished product auxiliary packaging

(1) Automatic stacking machine

(2) Baler

(3) Transfer conveyor

Raw Materials:

The raw materials are mainly from various pulp boards such as reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, and waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. Waste paper, widely sourced and easy to collect. The required operator is 5 people/class: 1 person in the pulping area, 1 person in the molding area, 2 people in the cart, and 1 person in the package.

Company Informations: